|

||||

|

|

Alex Askaroff has spent a lifetime in the sewing industry and is considered one of the foremost experts of pioneering machines and their inventors. He has written extensively for trade magazines, radio, television, books and publications worldwide.

Over the last few decades 'the sewing machine guru' has been painstakingly building these pages to encourage enthusiasts around the Globe to collect and treasure old sewing machines.

See Alex Askaroff on Youtube: http://www.youtube.com/watch?v=8-NVWFkm0sA&list=UL

|

|||

|

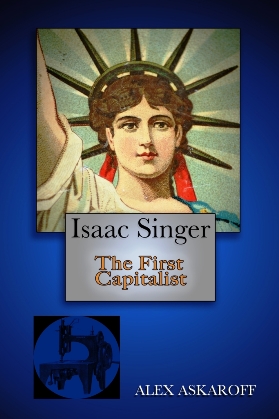

By Alex Askaroff In 1851 Isaac Singer brought onto the market the first practical sewing machine in history. He had combined all the ideas that had gone before to make a machine that actually worked. The result was explosive. By the 1870ís the humble sewing machine had become the most wanted item on the planet. Why? Because with it, anyone could pop down their local market on Saturday and wear a new dress to church on Sunday! Cheap material from the Northern Powerhouses, and the sewing machine, meant that beautiful clothes were no longer the sole domain of the upper classes. Here is the fascinating story of the rise and fall of Singer manufacturing in Britain, brought to you by world renowned author Alex Askaroff. Available ON ANY portable device, phone or PC via Amazon all around the world. Instantly downloaded with the FREE Kindle reading App. AND FREE ON KINDLE UNLIMITED or $3. The Rise And Fall Of Singer Manufacturing In Britain By Alex Askaroff The Rise And Fall Of Singer Manufacturing In Britain By Alex Askaroff

|

||||

|

Most of us know the name Singer but few are aware of his amazing life story, his rags to riches journey from a little runaway to one of the richest men of his age. The story of Isaac Merritt Singer will blow your mind, his wives and lovers his castles and palaces all built on the back of one of the greatest inventions of the 19th century. For the first time the most complete story of a forgotten giant is brought to you by Alex Askaroff. News Flash! Alex's books are now all available to download or buy as paperback on Amazon worldwide.

"This

may just be the best book I've ever read."

"My five grandchildren are

reading this book aloud to each other from my Kindle every Sunday.

The way it's written you can just imagine walking

beside him seeing the things he does. News Flash! Alex's books are now all available to download or buy as paperback on Amazon worldwide.

|

||||

|

Well that's it, I do hope you enjoyed my work. I have spent a lifetime collecting, researching and writing these pages and I love to hear from people so drop me a line and let me know what you thought: alexsussex@aol.com. Also if you have any information to add I would love to put it on my site.

Alex

Askaroff

Hello Alex, I just wanted to drop a quick wee email to congratulate you on such a wonderfully written and informative article about the Kilbowie Singer factory.

I learned a great many things about my local history and where my

machine was built.

Thank you for writing such an informative yet, enjoyable piece.

Thank you,

Charlie Wallhead

Charlie In Utopia Dressmaking and Costumery

Great work as always Alex. Keep it up. I have to say the sewing machine history saga would make a wonderful period drama.

Barry Jones

Thank you for sharing these

wonderful bits of history with us!

Barbara G Dowdy

USA

Great article...also I LOVE your informational videos on Youtube.

Rhonda Trent

This work of yours needs to be

taken to a movie producer! I know I'd love to see it on a big

screen!

Thanks for sharing your wonderful work with us! Cece Harpo Thank you Alex for sharing your hard work and knowledge with all of us enthusiastic collectors and sewers around the world! Susan Stuklis Fancy a funny FREE read: Ena Wilf & The One-Armed Machinist

Sir Sewlot, protector of the Sewalot Site

|

||||

|

|

|

|||

|

CONTACT: alexsussex@aol.com Copyright ©

As a

new collector I have found your site

has increased my knowledge in

a short time to a degree

that I couldn't have

imagined.

|

||||