|

||||

|

|

Alex has spent a lifetime in the sewing industry and is considered one of the foremost experts of pioneering machines and their inventors. He has written extensively for trade magazines, radio, television, books and publications world wide.

No1

New Release Amazon, out now!

Most of us know the name Singer but few are aware of

his amazing life story, his rags to riches journey from a little runaway

to one of the richest men of his age. The story of Isaac Merritt Singer

will blow your mind, his wives and lovers his castles and palaces all

built on the back of one of the greatest inventions of the 19th century.

For the first time the most complete story of a forgotten giant is

brought to you by Alex Askaroff.

No1

New Release Amazon, available now on Amazon

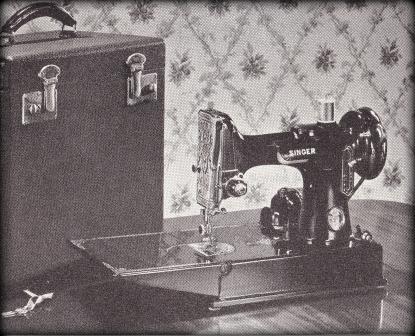

Singer Featherweights

The Perfect

Portable

By

Alex I Askaroff

|

|||

|

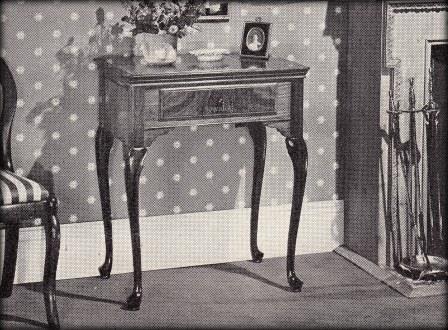

Since the invention of the humble sewing machine in the 1840ís it is said that over 100,000 different types and models have hit the markets around the world. Amazingly out of that mountain of machines, one stands head and shoulders above the rest. It has had poems written about it, eulogies, books, articles and a thousand imitations. It was so perfect in its original design and construction that it sold for four decades with hardly a change. It was made out of a material that most people had never seen before, a third of the weight of other machines. Its final death throws, in the 1960's, were self-inflicted. It was made of such high quality materials that it priced itself out of a market which was being flooded with cheap imports from emerging manufacturing nations. The bonus to us as quilters and collectors is that a machine designed before the outbreak of World War Two can still out sew most modern models. The machine that we are going to investigate here is the quilters dream or to you and me, the perfect portable, the Singer model 221 Featherweight. Let's get a few facts out of the way first. From 1933 up until 1969 approximately 3.5 million Singer Featherweights were made. Why? Because they are one of the finest stitching sewing machines on the planet. Originally, like the Model T Ford they only came in black but later models were crinkle, tan, mint and white. Some shops still had stock of Featherweights as late as 1971 where the price had dropped to £44, less than it had been selling for 30 years earlier. The Singer Featherweight model 221 sold from the 1930's right up until the last stock disappeared from the Singer shops in the early 1970's. White Singer 221 The last few were white with internal belt driven shafts that made for smoother power transition. Decoration changed from the early extravagant work (known as Egyptian scroll) to striated (see 222k further down) and prism decal to finally plain painted side plates in white, tan and mint. It is difficult to put into words why the Singer 221 has such appeal. Is it its size or shape, perhaps it is the beautiful purr it makes when it sews, or is it just because itís drop dead gorgeous? Was it the way everything was designed to fit so neatly into its protective box or the way, at top speed, the machine hardy vibrated. Maybe itís the ease of maintenance (which we will discuss later), or the way it draws a crowd every time it is used in public. I have a feeling that it is a little of all of these things but at the top of the list has to be its sewing performance. To quilters and professional machinists, from Haute Couture seamstresses to jobbing curtain makers, that is the largest box that the Featherweight ticks. The 221 does no fancy stitching (unless you have a go with some of the attachments), basically the needle goes up and down and the machine goes forwards and backwards, but boy does it do it beautifully. The 221 is a performer of outstanding ability, the Rudolf Nureyev of its day. The Featherweight box was the perfect protective case, strong, protective and reasonably light. It is one of the reasons so many have survived in great condition. A bonus is that, because the Featherweight has a standard low shank fitting, many new feet (like 1/4" quilting feet or free-motion-feet) will pop straight onto the machine. There were only a handful of original attachments supplied with the machine as standard but well over 100 will fit the Featherweight, even a zig-zag foot! It may be basic, but a well set up Featherweight handles multiple fabrics and thicknesses with ease. That's down to the superb design and engineering. They say a team of Singer's finest American engineers worked on the 221 design for over four years, perfecting each and every part until they had produced the equivalent, in evolution terms, of the shark, something so perfect that there was little else to do to it. Tooling was completed in the Elizabethport factory in New Jersey and by the early 1930's the first Singer 221 Featherweights were being tried and tested. Although Singer had been using aluminium machines as early as the 1920's the Singer Featherweight was first introduced at the 1933 World's Fair in Chicago, USA. It was the most expensive domestic sewing machine that they had ever manufactured and took the fair by storm, knocking all other contenders out cold and confirming once again that Singer made the finest sewing machines on planet earth. However there was a major problem, even with their clever hire-purchase scheme (invented by Edward Clark, Isaac Singer's business partner in 1855), America was entering the depths of their Great Depression and sales were consequently poor. Then bring on the storm clouds of WW2 and there was little hope for the 'perfect portable'. By 1936 Singer was already retooling for arms contracts from the government and it looked like the Singer Featherweight would be destined for a short life. Singer had been very helpful with the war effort, making everything from machine gun bullets to No36 Mills Bombs (hand grenades marked SMC, Singer Manufacturing Company). It is said that as hostilities came to an end Singer had back orders for over 3,500,000 machines. This was the most difficult time to obtain a new sewing machine. When customers visited their local Singer shops and asked for a 'new' sewing machine the reply would often be "Wouldn't we all like one madam!" They were then put on a waiting list (that was up to 18 months long) and contacted as soon as one was available. Things are a little different today. After the Second World War Singer returned to manufacturing in a big way and luckily for us the jewel in their crown had not been forgotten. Sales boomed and despite the cost, the little black Featherweight started to gain an unparalleled reputation for excellence. More and more dressmakers and seamstresses were spotted on busses and in the street carrying the perfect portable. Luckily the low shank standard fitting allows most new feet (like even feed feet) to drop on a treat. Now in Britain, a clever team of Singer engineers had taken the Singer 221 apart and performed a minor miracle. The design department at Kilbowie in Scotland took the 221 a step further by creating the fabulous Singer free-arm model 222k. The first Singer Featherweight free-arms were on sale by the mid 1950's. Now the 222k is basically the same Featherweight with the bonus of a free-arm sleeve and a drop feed for free-motion quilting. Priced at £66 in 1958 (when the average wage in the UK was around £6 per week) they were the most expensive sewing machine on the market and consequently sold in very limited numbers. They are rare beasties and command large sums today. For example between 1955 and 1960 less than 1,300 model 222k's were sold in the US. In the same period over 1,000,000 model 221's were sold! Singer Featherweight model 222k Sewing Machine The benefit of the 222k was a free arm sleeve and a drop feed for free motion quilting. Notice the striated later face plate. Interestingly Bernina had dominated the free-arm market. By 1960 they were the world No1 suppliers of free-arm machines. Singer needed to catch up fast. The Singer 222k was only ever made in Kilbowie on the banks of The Clyde in Scotland. It was made in very limited numbers. Note the sew-darn lever, only on the 222k. It simply dropped the teeth. I have a YouTube clip of it in action, just type Alex Askaroff into YouTube.

All the British Featherweights were made at largest Singer factory of its kind. It was on the banks of the River Clyde in Scotland and at its peak reported to employ around 14,000 people, on 24hr shift work, with over 2,000 just on their furniture, box and cabinet side. They even had their own railway line, stations and docks. They managed their own forests for timber. Nearly everybody in the area worked for Singer. Accurate time keeping with such a large workforce was essential. Singerís solution was to build the largest clock tower in the world with four back-lit clocks with faces over 26ft wide. It could be seen from just about every house in the district. There was little excuse to be late. The factory finally closed its doors in 1979 after nearly 100 years of production and the whole lot (including the largest clock in the world) was flattened. There was a story that in the early days of the Singer factory the workforce had terrible time keeping and a million excuses why they were late. Singer's solution was a clock tower bigger than Big Ben's clock tower in London. There was little excuse not to know the time when the largest clock in the world was staring down at you! The clock faces were 26ft wide and illuminated at night. The steel industry, ship building and Singer all collapsed at around the same time at Clydebank. For a generation the area became decimated. I go into it in detail in my book on the collapse of Singer manufacturing $3, The Rise And Fall Of Singer Manufacturing In Britain. The free-arm Featherweight was only ever produced in the Kilbowie factory. Singer also had the bonus of war surplus aluminium and legend tells that many of the post war machines especially the 201k, 221k and 222k had recycled parts in them from Spitfires, Hurricanes and heavens knows what else. To begin with, like Henry Ford, you could have any color Featherweight as long as it was black! But in later years, depending on which factory made the machine it came in several different coats. Even the military had drab black crinkle ones that are highly collectible today. The final models in the late 1960's were white with slight internal modifications (including a smoother and quieter shaft belt drive). More recently there has been some outstanding paint jobs on the 221's creating customers very own unique machines. Photo with kind permission of Desk Dave's Featherweight Factory, Nicholasville, Kentucky. Many Featherweight have undergone startling transformations and these 'pimped' machines can cost several thousand dollars. Several have become collectible in their own right. Originally the 1933 World's Fair Featherweight's were the most valuable but some of these are quickly catching up. What an eye catching machine to turn up at quilting with! This stunning Featherweight with its antique American flag was saved and rebuilt by specialist Rick Armao of RM Central Sales LLC in Wisconsin. Dating your Singer Featherweight is easy, simply turn it over and look at the serial number then Google it for the year it was made. I do have a page on this site on Singer serial numbers. Due to the flourishing of internet auction sites the Singer Featherweight is easily obtainable today and still represents superb value. Remember that they cost several months wages when they were made and, to me, most still seem to be as cheap as chips. A quality product for an economy price. In 1951, to celebrate 100yrs since Isaac Merritt Singer patented his first sewing machine, Singer put this special badge on almost every machine that left their factories during the 12 months. Featherweights with this badge often command a higher price in auction. If you buy that 'perfect portable' your very own 'quilters dream' (with its narrow foot so ideal for piecing small work) remember there are only three rules, condition, condition and, you guessed it, condition. Maintenance is so simple itís untrue and I have a complete YouTube clip on servicing your Featherweight. The machines donít like to be messed around with, they're workhorses and unless you have a specific problem leave well alone. They were designed to run in fluff (unlike todayís machines where it clogs the gears) so they don't need to be spotless. Occasionally remove any excess lint with a vacuum cleaner or a brush, then put a drop of quality sewing machine oil into each oil hole. A thumb nut holds the bottom plate on to allow access to the underneath oiling. If you sew every day, put in one drop per month, if you sew occasionally use one drop a year. After cleaning and oiling leave overnight then run a fresh piece of cotton through the machine and wipe over. Itís as simple as that. Over maintenance can severely impair your Featherweights sewing performance. The other great news is that just about every piece on the models is still available online so if something does break it is replaceable. Growing up in the sewing trade I have often asked my customers why they stick to sewing with these old classics. Many cannot put it into words but there is one common theme, the Singer Featherweight, that perfect little portable, puts a smile on your face every time you use it. It's never easy to put a price on things in this messy world today. However that one thing alone might just be priceless. Now a little more about the fabulous Singer 222k. From 1953 Singer also produced the amazing Singer 222k in limited numbers and only from Kilbowie in Clydebank, Scotland. Around 110,000 Singer 222k's were made. It took off slowly until the 1958 World Fair in Brussels where the whole back wall of the Singer stand was just model 222k's. However due to their high price they never sold in the same numbers and are dearly sought after today. At one point the 222k was the highest priced sewing machine in the world. The Singer model 222k sewing machine

This beautiful machine was the result of months of design work by some of the finest engineers in the sewing world. The result was one of the best sewing machines of all time. The Singer 221 and Singer 222 sewing machines are still amazingly popular amongst professionals and perfectionists alike. The image above is the model 222k made exclusively in Kilbowie, Clydebank, Scotland. The big difference is the free-arm sliding removable work area. The model 222 has been referred to as the Queen of Singers.

Made in limited numbers compared to her older sister the Singer model 221 she is rare and sought after and may go down in history as the finest Singer ever produced. Serial number dating can give you a date of manufacture but not a date of sale. A machine could have been sitting around for years in some dusty stock room before it was finally sold. This is why many receipts do not tally up with the manufacturing dates.

The basic difference between the 221 and the 222 is the free-arm sleeve and the drop feed lever. Both machines are similar and make perfect stitches when set correctly. They have become collector-classics and with almost every part still available or being made they will probably last forever. One of the main reasons is that the needlebar can only move up-and-down, held in positing by bronze bearings. There was no other movement (unlike modern machines where the needle is all wobbly). This allowed for near perfect straight stitching through a variety of fabrics. Even today the Singer Featherweight will out-stitch most modern sewing machines.

Featherweight model 221k

After WW2 Singers, who had been busy helping with the war effort, started to make sewing machines again. In 1945 they started a huge advertising campaign to recapture their market. Amazingly they had over 3,500,000 back orders for sewing machines which caused huge waiting lists. Traditionally by 1950 you could wait up to 18 months for the sewing machine that you ordered! Bit different today eh! LOOK THEY'RE HERE AT LAST! In 1945 the Singer Sewing Machine Company started, once again, to advertise vigorously to American housewives. Order today and be the first to proudly carry a Singer over your threshold!

Interesting to note that by 1960 the Singer

Featherweight

was being targeted at male machinists. Most of us know the name Singer but few are aware of his amazing life story, his rags to riches journey from a little runaway to one of the richest men of his age. The story of Isaac Merritt Singer will blow your mind, his wives and lovers his castles and palaces all built on the back of one of the greatest inventions of the 19th century. For the first time the most complete story of a forgotten giant is brought to you by Alex Askaroff. News Flash! Alex's books are now all available to download or buy as paperback on Amazon worldwide.

"This

may just be the best book I've ever read."

"My five grandchildren are

reading this book aloud to each other from my Kindle every Sunday.

The way it's written you can just imagine walking

beside him seeing the things he does. News Flash! Alex's books are now all available to download or buy as paperback on Amazon worldwide. See Alex Askaroff present a Featherweight sewing machine on YouTube. http://www.youtube.com/watch?v=3mJYS44Vc8c&list=UL

|

||||

|

I do hope you enjoy my work. I spend countless hours researching and writing these pages and I love to hear from people so drop me a line and let me know what you thought: alexsussex@aol.com Alex

Hi Alex

|

||||

|

|

|

|||

Singer 221 sewing machine and Singer Featherweight sewing machine model 222k

|

||||